Lubrication equipment for aircraft servicing

SUCCESS STORY

Lubrication equipment for aircraft servicing

An air base located in Torrejón de Ardoz (Madrid) required lubrication equipment in some of their maintenance hangars dedicated to servicing forest fire fighting and SAR (Search and Rescue) aircraft.

The existing aircraft greasing system used manual grease guns, which led to slow and complicated servicing processes, especially for seaplanes. For maintenance purposes they used a special airplane grease, supplied in small 5 kg pails. These grease pails and the grease supplying method proved to be inefficient and time-consuming, highlighting that using small pails is not a practical and time-efficient approach.

Challenges to solve

Avoid using manual grease guns

Reduce aircraft maintenance downtime

Reduce grease storage and purchasing costs

This is how we face the project

Our distributor, Importaciones Industriales, suggested using different equipment to meet the client’s needs. To meet the main requirement of various grease points without using time consuming manual grease guns.

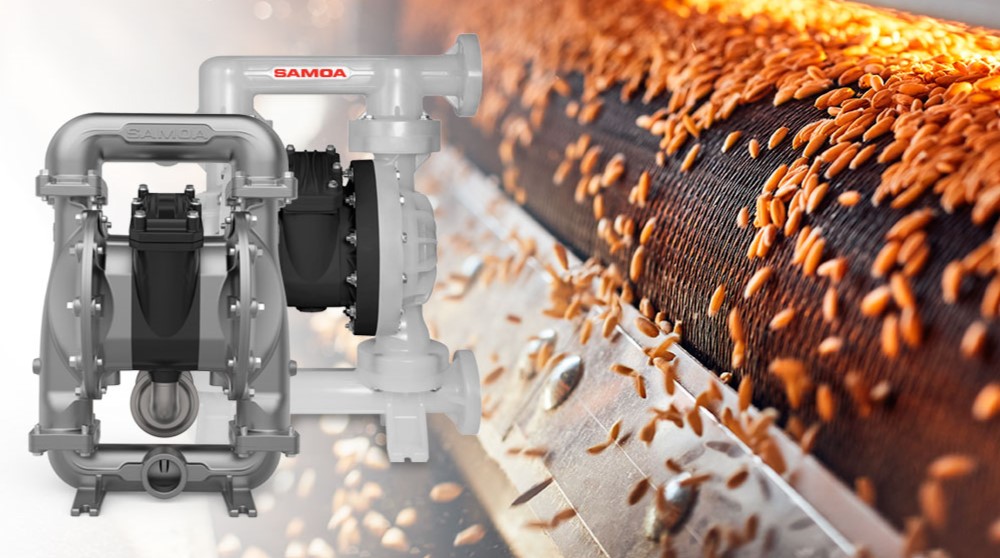

The installation consisted of a PM35 grease piston pump, equipped with a follower plate, as well as a hose reel and a high-pressure grease gun.

The PM35 60:1 grease piston pump was supplied with a drum cover and a follower plate kit, that allows dispensing grease directly from the 20 kg drums. Due to the very high viscosity of the grease, a weighted follower plate was used instead of the follower plate included in the kit. This change allows the follower plate to function correctly, preventing air pockects in the grease.

The RM34 heavy-duty hose reel, suitable for grease, with a 20 m hose, allows the technicians to access different grease application points, even those on the upper parts of the aircraft, facilitating the product application. The high-pressure grease gun used for dispensing grease, requires less effort and facilitates the grease application. Additionally, these high pressure grease guns provide precision dispensing.

The solution

With the SAMOA equipment installed, the end user noted a reduction in servicing time and highlighted the ease of access to any greasing point, even the difficult ones. The customer was very satisfied with our pump features, especially with the pump feed pressure and the flow rate obtained.

SAMOA’s piston pumps are designed for a quick reciprocating action that prevent stalling during operation and don’t require the use of a lubricator. The air motor, designed to avoid icing through an efficient heat transfer, has no springs that could wear and cause failures, minimizing the likelihood of downtimes during operation.

SAMOA’s hose reels are designed for a long life and trouble-free operation. They incorporate a special fatigue resistant steel spring, that is tested for twenty-thousand cycles. Our hose reels are manufactured with an epoxy powder coating, for wear resistance improvement, and using high quality hoses.

Real success stories about our products

Check out our best application stories.