Lubrication equipment in underground mining

SUCCESS STORY

Lubrication equipment in underground mining

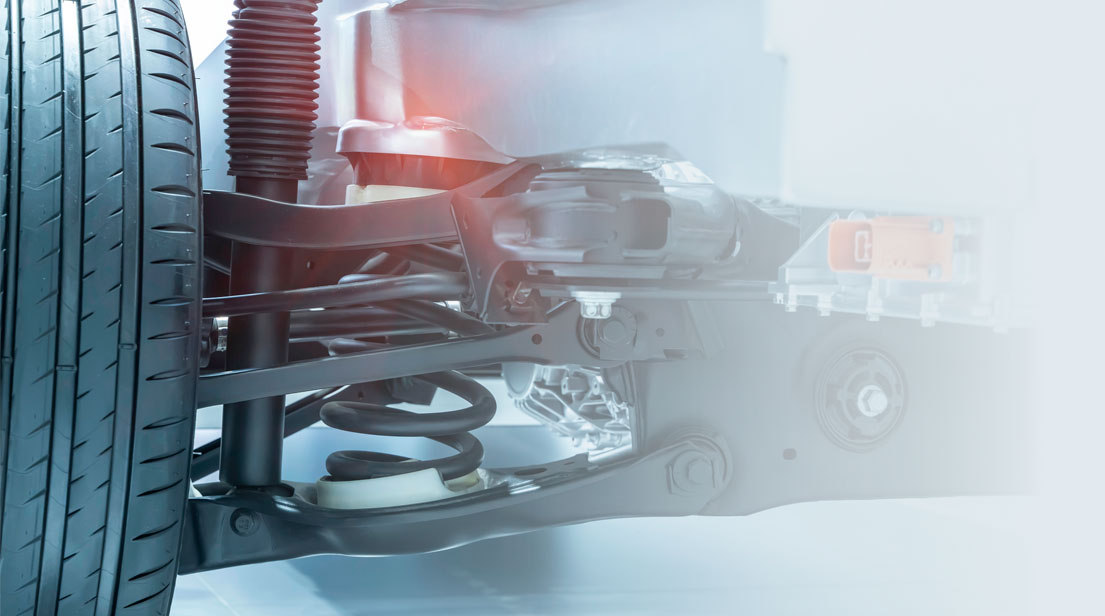

A mining company faced a number of challenges as they needed to supply hydraulic and engine oils to their mining vehicles. Their underground setting posed some extreme working conditions, first due to its depth of 550 m which challenged the equipment installation, and second, because of its ATEX environment.

The company required a service facility nearby the mine’s operational area, to minimize their vehicle’s maintenance downtimes. It was also crucial that the equipment was durable and could provide reliable performance. The main reason was that their harsh working conditions included the possibility of impacts from heavy machinery.

Challenges to solve

Service area with intensive use

Withstand severe undergound working environment

Reducing mining vehicles maintenance downtime

This is how we face the project

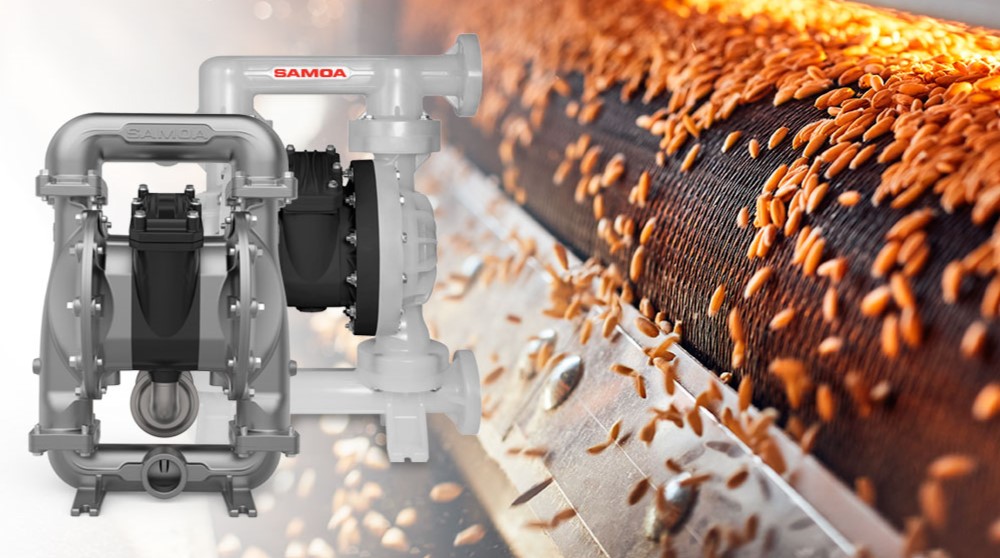

As the end user required an installation to store and supply the aforementioned oils, the following SAMOA products were selected: oil piston pumps, double diaphragm pumps, hose reels, metered control valves and waste fluid management units.

SAMOA’s high –performance piston pumps PM45 6:1, for pumping high viscosity oils, and PM35 5:1, for pumping medium viscosity oils, were installed. Both of them are used to supply several points simultaneously.

The installation also included two types of heavy-duty hose reels. The first type is the RM-12L model, ½" x 15 m, installed for oil applications. The second type is the RM-34 model, ¾" x 15 m, suitable for AdBlue, windshield wash solutions and detergents. Both operate at low pressure and withstand use and abuse of Intensive Duty applications. For the dispensing points in servicing, SAMOA equipped the installation with EC70 high flow electronic control valves, manufactured in aluminium, which are suitable for oil and other fluids.

The solution

SAMOA equipment is designed and manufactured with high-quality materials to achieve optimal performance in heavy-duty applications, with extreme working conditions and temperatures, such as the ones mentioned for this application.

Our PM35 and PM45 proven air motors are operated by a valve mounted on the piston rod, ensuring a fast-reciprocating action for non-stalling operation, guaranteeing the reliability of the equipment installed. This, in turn, translates into faster maintenance of low-speed vehicles. The air motor has no energy consuming spring, preventing motor failures. Its air exhaust is dimensioned for an efficient heat transfer, avoiding icing during operation. SAMOA’s piston pumps are designed to be used in extreme conditions without the need of a lubricator.

SAMOA’s hose reels are designed with a special fatigue-resistant steel spring that guarantees even tension at every point. They are tested for twenty thousand cycles, ensuring a long life. These hose reels are manufactured using only high-quality hoses, specially formulated for the equipment, and epoxy powder coated parts for increased wear resistance, making them ideal for harsh environments and heavy-duty applications. This not only ensures a longer life compared to other brands but also makes them a reliable choice for demanding situations.

The SAMOA equipment installed was able to successfully overcome such a demanding application and special conditions for the following reasons:

Our heavy-duty lubrication equipment proved an unmatched reliability, effortlessly working in this environment.

We managed to enable the servicing of low speed vehicles, faster than competitors.

Image gallery

Real success stories about our products

Check out our best application stories.