A lubrication equipment in mining service trucks

SUCCESS STORY

A lubrication equipment in mining service trucks

The end user, MNSA Maintenance Company, is responsible for servicing the nickel mines SLN (Societé le Nickel) in New Caledonia, the fourth largest nickel production market in the world. MNSA has been using SAMOA equipment for over thirteen years, servicing all mine vehicles and machinery with their fleet of fourteen service trucks.

The mine operates 24/7, so these service trucks must always be prepared to service mine vehicles when necessary. It is paramount that mining vehicles and machinery are well lubricated, to avoid any downtime caused by vehicle breakdowns.Proper lubrication can reduce work delays, decrease productivity losses and avoid high costs.

Challenges to solve

Withstand heavy-duty operation, such as severe weather conditions or impacts

Fast transfer of greases and lubricants

Equipment reliability

This is how we face the project

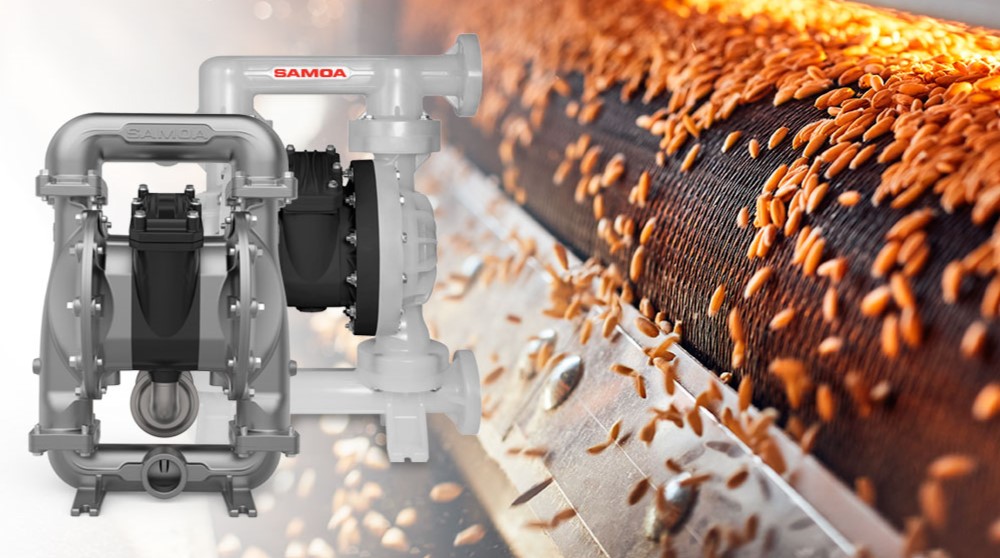

Mining vehicle maintenance requires special equipment built with high-quality materials to ensure optimum performance in extreme working conditions and temperatures. In addition, such equipment needs highly reliable technology to achieve the required lubrication demands. Hence, the equipment for this installation was selected, considering both the transferred fluid characteristics and the pumping location. SAMOA offers high-capacity pumps for this application, with high-capacity reels and high-flow control valves.

Two grease piston pump models were installed. First, the high-performance pump PM60 12:1 (532130), suitable for transferring large grease volumes (greases up to NLGI-2). Manufactured with high-quality materials allowing optimum performance in extreme working and temperature conditions, such as outdoor applications. This pump is used for tank refilling, even when using long pipes or hoses. Second, the pump PM35 60:1 (530610), is used in forced lubrication with high delivery rates (greases up to NLGI-2).

Two piston pumps designed for transferring and supplying oil were also incorporated into the installation. One of them is a piston pump PM2 3:1 (354120) for applications where medium flow rates is needed. For situations requiring long distance oil supply with high flow rates, we included a piston pump PM4 5:1 (347120).

SAMOA installed three different open type hose reels, manufactured in steel, for regular use and abuse in Intensive Duty applications. The RM100 (508225) model is suitable for high flow rates at medium and low pressure, while the RM150 and RM34 models (508810, 505224) are only for low pressure. To dispense the fluid at each delivery point, we chose two types of electronic metered control valves, EC30 model (365535) and EC70 (365655) model for high flow. Both products are suitable for oil and other fluids and manufactured in aluminum.

The solution

SAMOA products are pivotal in minimizing maintenance downtime for mining vehicles, thereby helping to mitigate productivity losses. Moreover, the use of high-quality materials and robust construction of SAMOA products is very important, particularly in regions where accessible workshops are scarce, like this case with no nearby workshops. This means that maintenance efficiency relies entirely on the equipment's performance.

SAMOA's proven air motors are designed with precision to function effectively in extreme conditions without requiring additional lubrication. Our PM35 and PM60 air motor design features a valve mounted on the piston rod, which instantly activates the air distribution valve once the piston reaches the end of its stroke, resulting in a fast-reciprocating action that prevents stalling. Notably, our air motor has no energy-consuming springs, which could lead to motor failures, and an efficient heat transfer design to prevent icing during pump operation. All these features ensure uninterrupted operation thanks to our piston pump reliability.

The reliability extends to SAMOA's hose reels, which guarantee a smooth operation of the servicing process. Our hose reels are designed with precision, featuring a special fatigue-resistant steel spring. To ensure their longevity and consistent tension at every point along the hose, they are rigorously tested through twenty thousand cycles. What further sets SAMOA's hose reels apart is the selection of high-quality hoses, specially formulated to meet the specific equipment demands. Moreover, to enhance their wear resistance, all components are coated with an epoxy powder, thereby ensuring they can withstand the demanding applications in mining environments.

Under these working conditions, SAMOA has successfully met the application and customer requirements for over thirteen years. MNSA’s general manager, Pierre Frogier, has highlighted the quality and satisfactory results of the equipment supplied by SAMOA over the years, as he stated with satisfaction: “We have been working with SAMOA equipment for thirteen years in our fleet of fourteen refueling trucks. The equipment quality and reliability, as well as the innovations, allow us to offer a quality service to our customers.”

Real success stories about our products

Check out our best application stories.